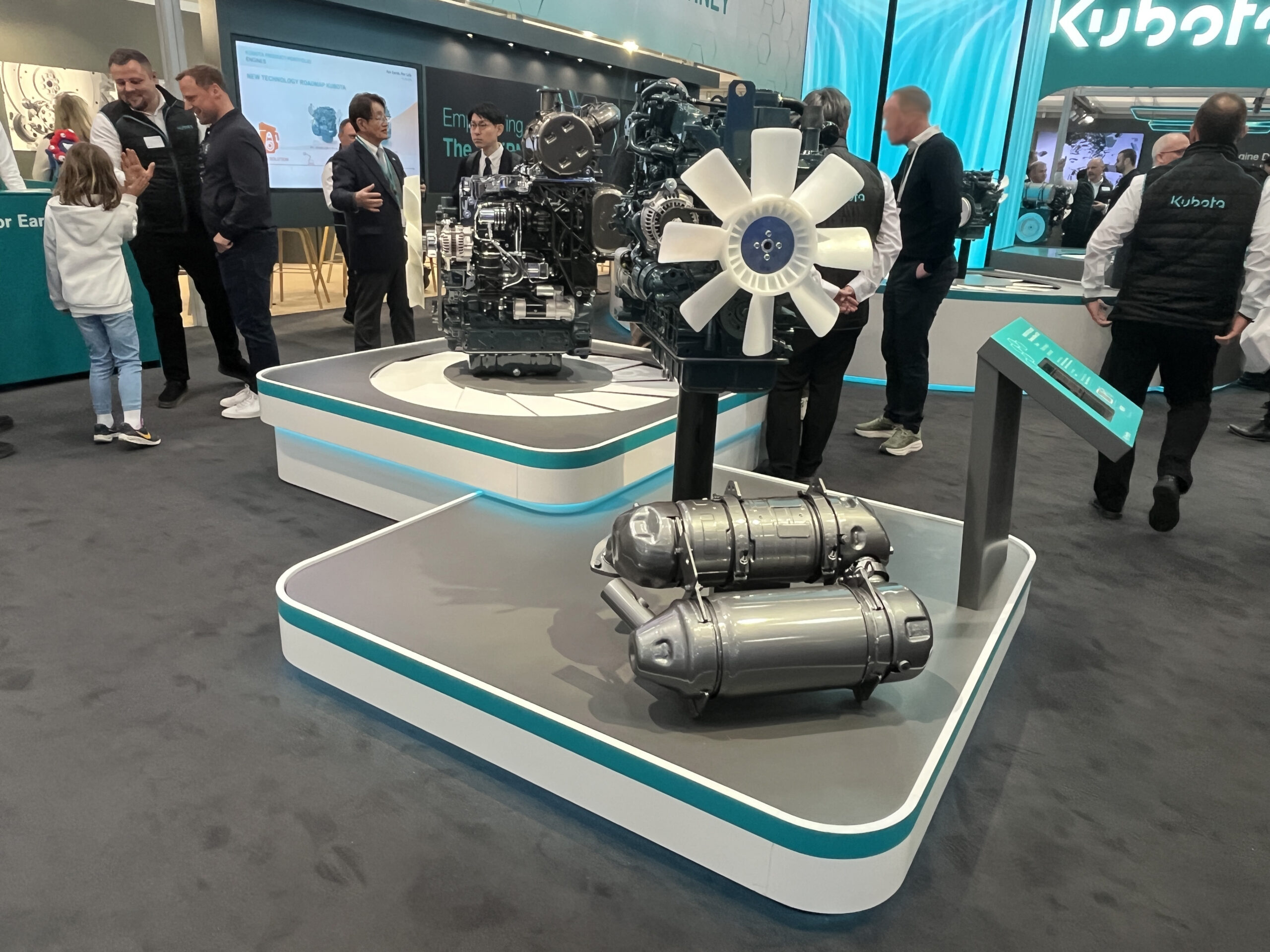

Engines for a Resilient Future

Kubota Engine line-up constantly growing to meet diverse needs

V3307 90kW Engine with Enhanced Power and Torque

Significant Power Upgrade

Since its mechanical specifications were introduced in 2005, the Kubota V3307 engine model has been available in various configurations, including DPF, DOC and Micro Hybrid options, within the power range of under 56 kW.

We are now pleased to announce the development of the new Kubota V3307-CR-TIE5-SCR high-output engine model.

Benefits of the New High-Output 3.3 L Engine

This compact 3.3 L, EPA/CARB Tier 4, EU Stage V compliant diesel engine provides a major increase in power and torque compared to the existing and popular V3307-CR-T Kubota engine model (further available with 56 kW of power and torque of 335 Nm).

The newly developed, more powerful re-designed and upgraded engine can provide 90 kW at 2400 rpm and 400 Nm of torque at 1500 rpm – but, crucially, with the same dimensions, compact design, easy installation and the advantages of one-sided maintenance convenience.

Compact Mixer by Kubota

Advanced SCR Technology

A feature of the new 90 kW V3307-CR-TIE5-SCR is a highly compact Selective Catalytic Reduction (SCR) system to reduce emissions – referred to as a Compact Mixer.

Its small dimensions allow operators to incorporate the after-treatment system more easily into machines and offers more installation flexibility.

Downsizing Benefits

The existing V3307 engine remains a very popular choice among customers. However, the new V3307 90kW's dimensions support downsizing from a 4 or 4.5 L engine to a 3.3 L model which offers a smaller footprint and architecture within machinery but with a significant boost in power and torque.

Areas of Application

This new engine is especially suitable for use within typical torque demanding applications such as telehandlers, highway construction equipment like rollers and pavers, multi-purpose vehicles including tool carriers and also wheel loaders.

Flexibility

Interchangeable options above and below 56 kW available

Compactness

Compact design for flexibility and easier installation

Lightweight

Lightweight yet sturdy design for improved fuel efficiency

Low Fuel Consumption

Enhanced efficiency for reduced lifetime costs and less CO2 emissions

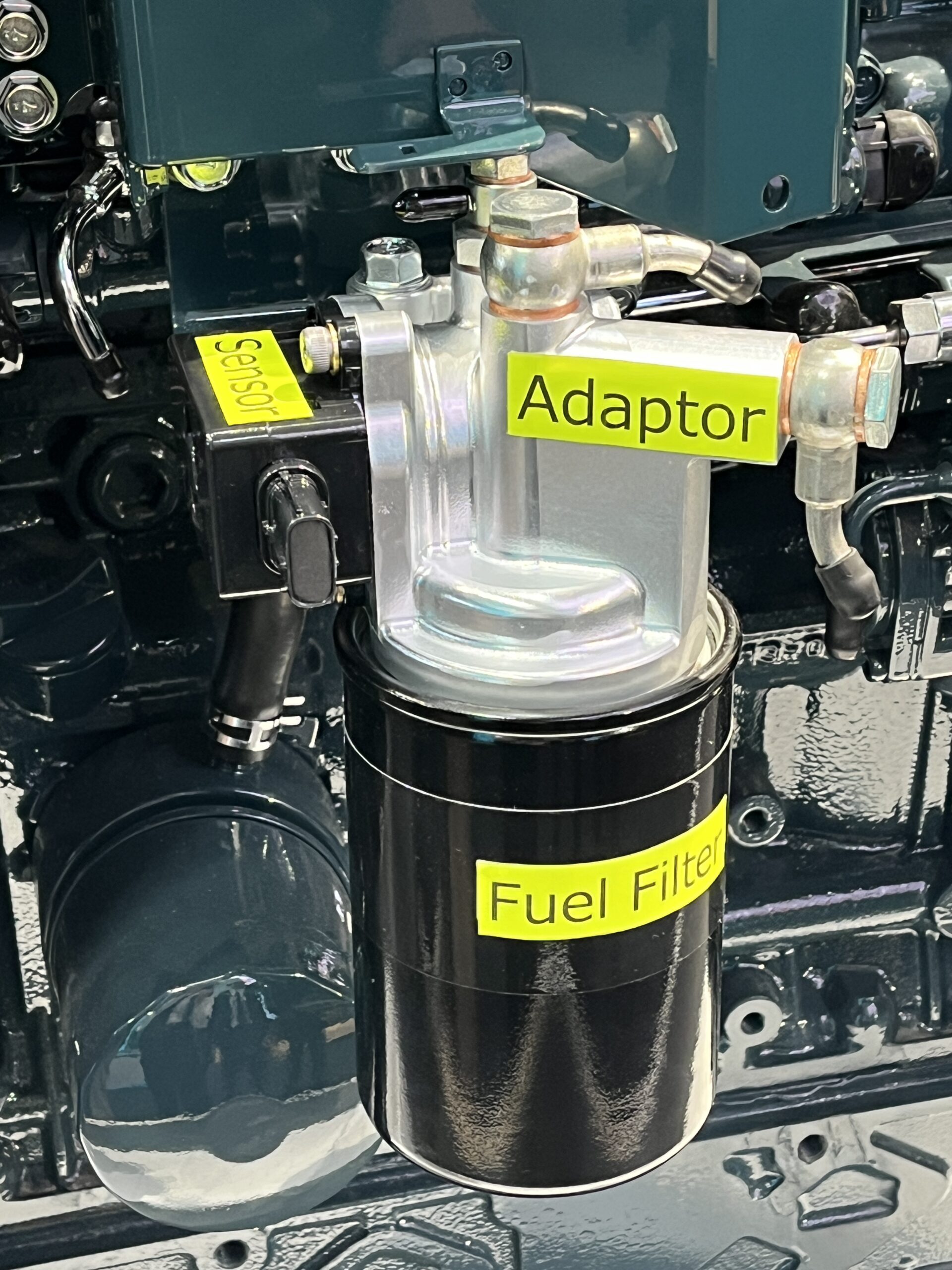

Cutting-Edge HVO Fuel Sensor

Real-Time Detection of Fuel Blend

At last Bauma show, we were able to present an engine equipped with a fuel monitoring sensor, developed by SUN-A Corporation, which can detect the blend of fuel which is being used in off-highway equipment – a likely vital tool in the future as the mandatory use of Hydrotreated Vegetable Oil (HVO) becomes more widespread.

HVO Responsive Technology

The new sensor is equipped with HVO responsive technology and can detect the fuel type in use in a machine in real time. The sensor measures the thermal properties of the fuel to accurately determine the HVO content.

If fuel with less than 90% HVO is supplied, the engine automatically restricts operation through the ECU. Kubota's unique design enables a compact structure that integrates the HVO sensor with the fuel filter.

The prototype of the new sensor is already working. The HVO sensor kit can be installed in all Kubota electronically controlled engines and can be used in various applications.

Fuel Monitoring for Increasing Environmental Requirements

Whereas there was a previous focus on sensors only detecting the amount of possible water moisture in fuel, the new Kubota sensor goes further by measuring and monitoring the level of bio-content in a fuel. This is likely to become an even more important subject in the future if pressure grows for legalised, audited fuel monitoring requirements.

This subject is becoming an increasingly important topic especially among rental companies and other end users.

What is HVO Fuel and What are the Advantages?

HVO stands for 'Hydrotreated Vegetable Oil'. It is a type of biofuel synthesised from vegetable oil or fats. Due to its properties similar to conventional diesel, it is becoming increasingly popular as an alternative fuel. The environmental benefits of HVO lead to reduced carbon emissions.

Real-Time HVO Detection

Continuous monitoring of fuel composition

Automatic Engine Control

Based on fuel quality detection

Compact Integration

Seamless integration with fuel filter

Contact Us

Address

Dormer Road Thame

Oxfordshire OX9 3UN

Telephone: 01844 268000

Fax: 08702 429729

Thanks!

Your message has been sent.